Chinese transmission and drivetrain manufacturer Greenland Technologies is throwing its hat in the equipment ring with its own line of all-electric, lithium-ion powered construction equipment, released under the moniker Hevi Equipment.

The launch serves as a rebranding of the company’s Greenland Machinery division and includes the GEL-1800 and GEL-5000 electric wheel loaders and the GEX-8000 electric excavator. Hevi says it has ambitious plans to expand into other product lines.

“It’s a sector that’s dominated by a very small handful of players, and they’re all diesel-focused,” says Greenland Technologies CEO Raymond Wang. “The U.S. is a prime market for us to electrify.”

The company started its research and development process in 2019 and quietly announced its entry into the construction equipment market in early 2021, with the first products arriving in the United States at the end of last year.

Working with partners was essential to ramp up production quickly while ensuring quality, notes Wang. Hevi partnered with a Chinese industrial heavy-equipment manufacturer on the mechanical components and CATL on the battery technology.

“Quality is super important from an adoption standpoint,” says Wang. “For the critical components, which is the battery system and the hydraulics, we didn’t want to try to take on that challenge ourselves.”

Hevi says the electric equipment has 60% less maintenance costs than an internal combustion engine due to the reduced number of moving parts. Meanwhile, the rechargeable lithium-ion battery offers substantial cost savings over diesel fuel. The machines can work indoors or in sensitive areas, such as around animals, because they emit no emissions or noise pollution.

“Our products support a company’s environmental, social and governance goals,” says Wang. “For our smallest vehicle, the equivalent diesel burns six to eight gallons of fuel per hour of operation. That’s a lot of carbon.”

The GEX-8000 features a fully openable cab.HeviDig Series Electric Excavators

The GEX-8000 features a fully openable cab.HeviDig Series Electric Excavators

The 8-ton GEX-8000 has a run time of nine hours on its LiFePo4 lithium-ion battery pack and can be charged to full capacity in two hours from an optional 90 kW output charging facility.

Hevi says the electric excavator packs plenty of torque regardless of rpm. The machine has a motor power of 63.2 horsepower, or 46.5 kilowatts.

The GEX-8000 has a maximum digging force of 36,878 pound-feet and a maximum digging depth of 7 feet 7 inches. It has a maximum travel speed of 9.3 mph when unloaded.

The machine comes standard with a fully openable cab, a leveler blade, a color display and air conditioning. Maintenance points are easily accessible, and a quick hitch enables secure changing of attachments.

While no telematics or machine control options are available at this time, Hevi has partnered with Cyngn to explore autonomous operation for future models of its products.

Hevi Equipment

Hevi Equipment

Load Series Electric Loaders

Two models of electric wheel loaders are available from Hevi, the 1.8-ton capacity GEL-1800 or the 5-ton capacity GEL-5000.

Like the GEX-8000, the loaders boast long operational capabilities, at eight hours for the GEL-500 and nine hours for the GEL-1800, and fast charging. Both machines are powered by a LiFePo4 lithium-ion battery. The GEL-1800 has a motor power of 102 horsepower, or 75 kilowatts, while the GEL-500 has a motor power of 160.9 horsepower, or 120 kilowatts.

The maximum dumping height of the GEL-1800 is 8 feet. The GEL-5000 has a maximum dump height of 11 feet 9 inches.

A 1.31-cubic-yard bucket comes standard on the GEL-1800. The GEL-500 has a 3.9-cubic-yard bucket.

The rear hood flips up for easy access to maintenance ports and the fuse box.

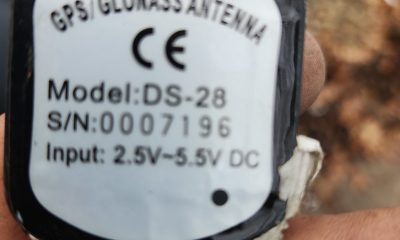

Hevi uses a CCS1 plug for its charging port.Hevi

Hevi uses a CCS1 plug for its charging port.Hevi

Purchasing and Maintenance

Hevi is solely focused on the U.S. market at this time, specifically the mid-Atlantic region due to the proximity to its North American headquarters in East Windsor, New Jersey.

The models are commercially available for sale and can be reserved and purchased directly through Hevi. The direct sales model helps Hevi keep its prices competitive with diesel-powered equipment, the company says. The current lead time for a new machine is six to eight months.

A five-year warranty on the battery is standard. Should the battery experience a performance loss of 25% or greater within the first five years, Hevi will give you a new one, the company says.

To further set itself apart from major manufacturers, no proprietary parts are used on Hevi Equipment. The manufacturer encourages owners to service the machines themselves or through its service partner TRG, a network of 54,000 repair shops for the tractor-trailer industry. TRG’s technicians will be trained to perform preventative maintenance and repairs on all of Hevi’s electric equipment, according to Hevi.

“Not pursuing a dealership model allows us to make the vehicles as accessible as possible for our clients,” says Wang. “If you want to replace a tire, then have at it. It’s a standard size tire. Go get it from any tire shop. Same thing with any side paneling, attachments or anything like that. Since we don’t have dealer service to cannibalize, we want to make it as simple as possible.”

Interested buyers in Maryland will also benefit from the recent passing of the Maryland Clean Cars Act of 2022. The legislation, which goes into effect July 1, provides a consumer incentive that covers 20% of the purchase price for electric heavy industrial equipment sold in the state. Hevi says it is the only product line in the U.S. that falls within the category.

Hevi EquipmentManufacturing Coming to the U.S.

Hevi EquipmentManufacturing Coming to the U.S.

Due to ongoing supply-chain issues, the equipment is currently manufactured and assembled in China, but Hevi plans to shift as much manufacturing to the U.S. as possible.

The company’s first U.S.-based assembly center will open in Baltimore, Maryland in July. The 54,000-square-foot facility will produce over 500 electric heavy equipment units per year when fully operational.

“We’re going to try to find as many local suppliers for critical components, and ultimately, our future vision is that the vehicles will then be not just assembled in the U.S. but made in the U.S. as well,” says Wang.

Greenland Technologies began operations in 2006 under the name Zhongchai Machinery in China.

Quick Specs

GEX-8000

- Operating Weight: 18,729 pounds

- Bucket Capacity: 0.33 cubic yards

- Lift Height: 13 feet 9 inches

- Digging Depth: 7 feet 7 inches

- Maximum Digging Force: 36,878 pound-feet

- Electric Drive Motor Rated Power: 63.2 horsepower

- Max Speed Unloaded: 9.3 mph

- Minimum Ground Clearance: 15 inches

- System Working Pressure: 28 MPa

- Battery Capacity: 140.95 kWh

- Battery Voltage: 618.24 V

- Operation Time: 9 hours

- Charge Time – 90 kWh: 1.5 hours

- Charge Time – 60 kWh: 3 hours

- Charge Time – 12 kWh: 12 hours

GEL-1800

- Load Capacity: 3,968 pounds

- Operating Weight: 11,464 pounds

- Battery Capacity: 140.95 kWh

- Battery Voltage: 618.24 V

- Operation Time: 9 hours

- Charging Time – 90 KW input: 1.5 hours

- Charging Time – 60 KW input: 2.5 hours

- Charging Time – 12 KW input: 13 hours

GEL-5000

- Load Capacity: 11,023 pounds

- Operating Weight: 39,683 pounds

- Battery Capacity: 282 kWh

- Battery Voltage: 618.24 V

- Operation Time: 8 hours

- Charging Time – 90 KW input: 3 hours

- Charging Time – 60 KW input: 5 hours

- Charging Time – 12 KW input: 23.5 hours

Business5 years ago

Business5 years ago

Business3 years ago

Business3 years ago

Tech3 years ago

Tech3 years ago

Tech2 years ago

Tech2 years ago