Just in time for funding from the $1 trillion federal infrastructure law to reach states, Dynapac is rolling out a new line of highway class pavers for the North American market.

The pavers, launched recently at World of Asphalt, have been completely redesigned and are being built at the company’s plant in South Carolina.

The line marks another first for the company, which was previously building the pavers for the U.S. market in China.

“The machine itself is exciting for us because we no longer have to produce the machine in China,” said Dynapac CEO Jamie Roush at the company’s booth. He noted that Dynapac previously produced a paver in Texas when Dynapac was owned by Atlas Copco, but production was later moved to China to lower costs. Dynapac has been part of the France-based Fayat Group since 2017.

He adds that the new pavers are completely redesigned from the ground up.

“It has zero DNA of the old machine for all the right reasons,” he says.

At World of Asphalt, the company displayed its new D30T paver decked out in an American flag design to highlight its new production location. The design, called the “Patriotic Package,” is available for customers, as well as the company’s trademark white with red lettering and trim or other custom designs.

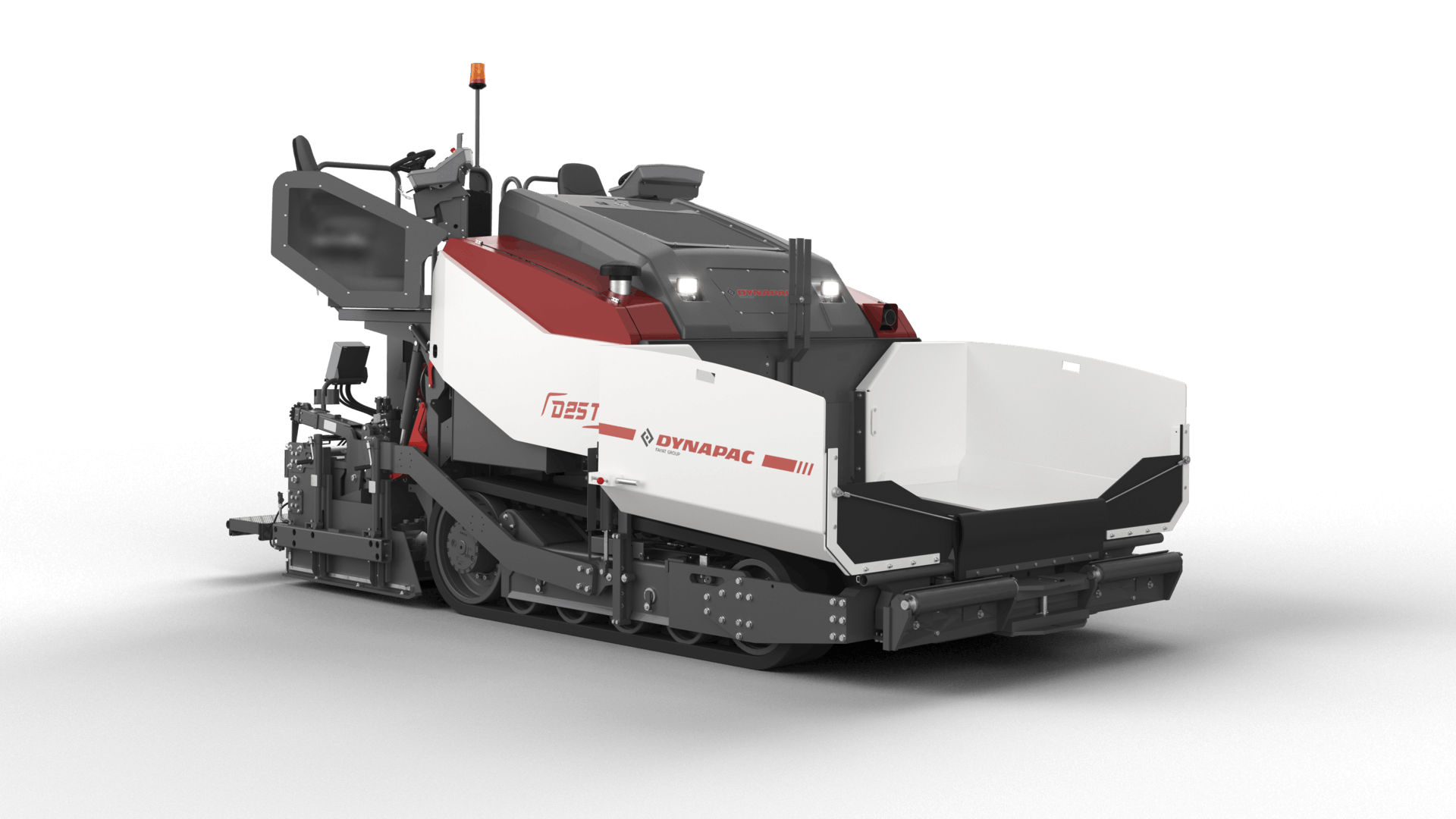

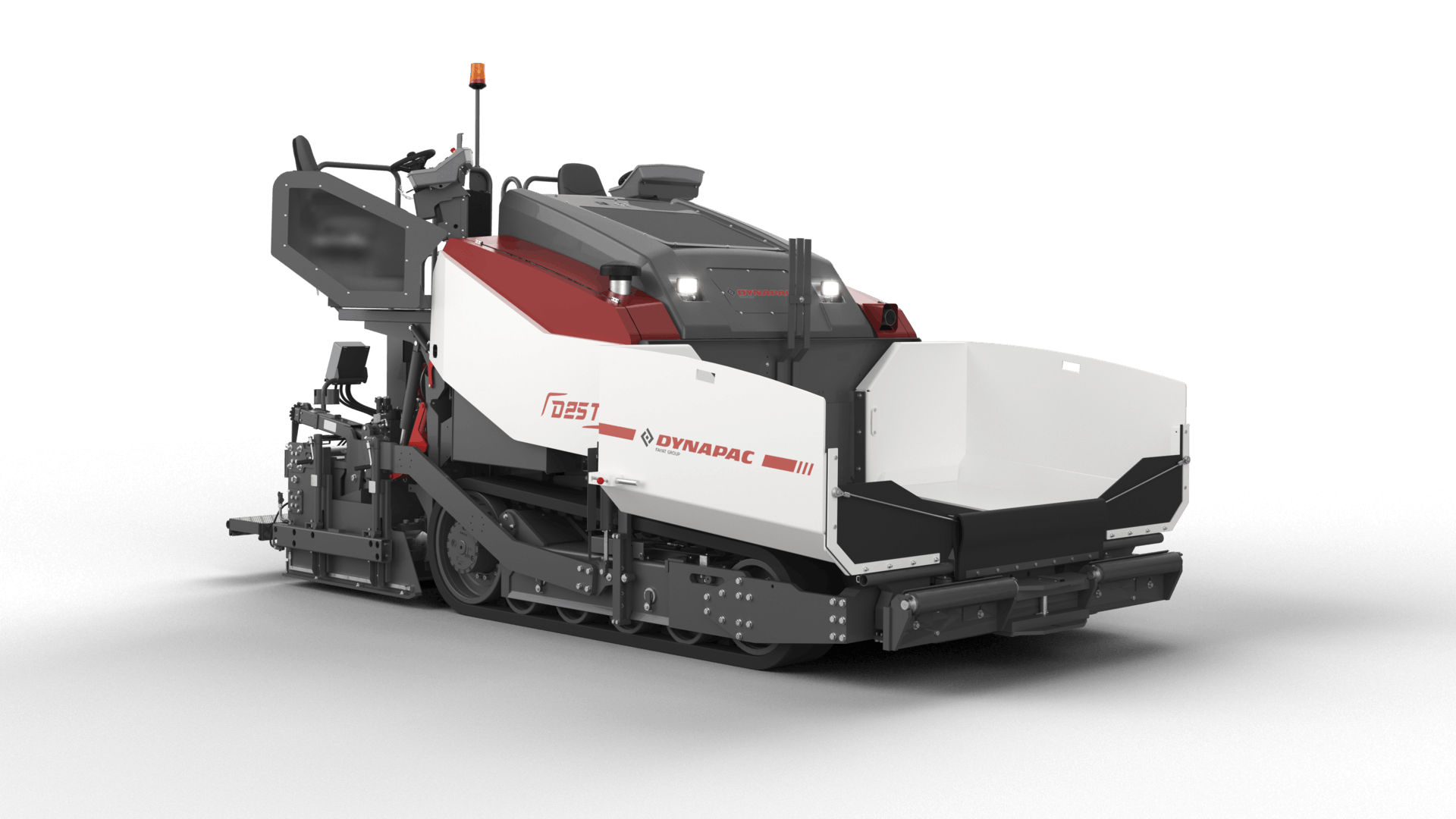

The 10-foot tracked D30T joins three other new models: the 10-foot wheeled D30W, the 8-foot tracked D25T and the 8-foot wheeled D25W.

The company also rolled out new screeds: the 8- to 16-foot Mat Master 16R and 10- to 20-foot Mat Master 20R.

The new Dynapac pavers are equipped with the company’s Mat Master screeds, which have a 30-year history.Equipment WorldThe pavers and screeds are designed for high-speed paving of thin or thick layers of asphalt and can be used on highway jobs, new construction or large commercial projects.

The new Dynapac pavers are equipped with the company’s Mat Master screeds, which have a 30-year history.Equipment WorldThe pavers and screeds are designed for high-speed paving of thin or thick layers of asphalt and can be used on highway jobs, new construction or large commercial projects.

When paving thin layers, the screeds can be operated with DiveStop and Active Screen Assist for high mat quality, the company says. DiveStop and the Safe Impact System also prevent bumps in the mat when pausing and resuming paving.

“DiveStop stops the screed from diving into the mat when it comes to a stop or is taking off,” says Vijay Palanisamy, Dynapac director of product marketing and communications. “There are no marks made in the mat when you stop.”

It also helps when paving thin layers, as slim as 1 to 2 inches, he says, because it puts upward pressure on the heavy-duty screed. “So now with that technology, the heavy-duty screed can be used for thick lift paving or thin lift paving.”

The pavers can reach travel speeds of up to 10 mph for quick repositioning at the beginning and end of the day, according to Dynapac.

The tracked pavers feature iTrack rubber tracks designed for increased wear life and low maintenance costs. The iTrack system automatically prevents the tracks from coming off when hitting an obstacle.

The iTrack tensioning system – the “i” stands for intelligent – keeps optimal track tension in forward and reverse, the company says. If there is inadequate tension, such as when hitting a loose pile of aggregate, it will automatically stop the paver to prevent the tracks from coming off and alert the operator.

Dynapac also beefed up the box frame design of the track system to reduce maintenance and increase durability. “Dynapac is the only one that offers this kind of a box frame design,” Palanisamy says. “It’s supported on the front and also on the side. Most manufacturers offer only support from the side.” The track frame provides rigidity, which reduces stress on the machine should it hit an obstacle.

The wheeled pavers feature Dynamic Suspension Control for increased tractive effort and paving quality, the company says. The wheels always maintain ground contact, even on soft and uneven surfaces, to prevent spinning. Along with improved traction, this avoids uneven screed movement if objects are run over, the company says.

Equipment WorldFor operators, the command station has dual independent consoles, and the platforms swing out to the sides for better viewing. The operator stations’ dashboards are equipped with ergonomic toggle and rocker switches and are organized for better feel and quicker learning time, according to Dynapac.

Equipment WorldFor operators, the command station has dual independent consoles, and the platforms swing out to the sides for better viewing. The operator stations’ dashboards are equipped with ergonomic toggle and rocker switches and are organized for better feel and quicker learning time, according to Dynapac.

The feed system offers multiple options for various paving scenarios:

- Proportional Dual Sensor Mode – Auger speed is controlled by ultrasonic sensors and the conveyor follows the auger speed.

- Proportional Quad Sensor Mode – Auger and conveyor work independently with their own sensors.

- Flow Gate – Optional flow gate for controlling the head of material.

Options for the pavers include Hydraulic Tunnel Extension, which prevents material from entering the track components, and an auto-lube system.

The pavers have integrated emulsion-spray equipment with tank and hose reel and a dedicated cleaning assist mode for conveyor, auger and screed. Dynapac says the front conveyor cover, which is under 10 inches, is the smallest on the market and enables easy hopper cleaning.

Equipment WorldThe electric Mat Master screeds are designed to heat up quickly with a new multi-zone heat control, which Dynapac calls a “fail-safe heating design.” That’s because the heating system has three sensors, one on the main screed and one on each extension. If one sensor fails, you don’t lose the heat because it automatically uses the next section’s heat sensor. The operator is then warned of the failed sensor.

Equipment WorldThe electric Mat Master screeds are designed to heat up quickly with a new multi-zone heat control, which Dynapac calls a “fail-safe heating design.” That’s because the heating system has three sensors, one on the main screed and one on each extension. If one sensor fails, you don’t lose the heat because it automatically uses the next section’s heat sensor. The operator is then warned of the failed sensor.

The screeds have two heating modes: Heat Boost for quick heating on cold mornings and Eco-Mode.

Eco-Mode enables paving at the lowest possible rpm, and ECO Zonal screed heating consumes less power and fuel, the company says.

The Mat Masters can not only handle warm mix asphalt and stone mix asphalt, but a variety of other mixes, including polymer modified and rubberized asphalt, according to Dynapac.

The screeds also feature Anti Drift Technology that eliminates the need for constant screed adjustments while paving, Dynapac says.

Equipment World

Equipment World

The company says it also gave the pavers its largest Anti Segregation Auger, at 17 inches in diameter, and its slimmest drive chain box to achieve homogenous mix.

The pavers even come with their own Flicker-free Generators for plugging in lights for night work. “The need of renting external generators and plugs are completely removed,” the company says.

The pavers can be outfitted with aftermarket machine control systems from Topcon or MOBA.

Quick specs

Tracked D30T

- Weight with screed: 45,200 lbs.

- Engine: Cummins 225 hp Tier 4 Final

- Screed: Mat Master 20R

- Paving widths: 10 to 20 feet

- Max layer thickness: 12 inches

Dynapac D30WDynapacWheeled D30W

Dynapac D30WDynapacWheeled D30W

- Weight with screed: 41,700 lbs.

- Engine: Cummins 225 hp Tier 4 Final

- Screed: Mat Master 20R

- Paving widths: 10 to 20 feet

- Max layer thickness: 12 inches

Tracked D25T

- Weight with screed: 37,950 lbs.

- Engine: Cummins 173 hp Tier 4 Final

- Screed: Mat Master 16R

- Paving widths: 8 to 16 feet

- Max layer thickness: 12 inches

Wheeled D25W

- Weight with screed: 35,750 lbs.

- Engine: Cummins 173 hp Tier 4 Final

- Screed: Mat Master 16R

- Paving widths: 8 to 16 feet

- Max layer thickness: 12 inches

Dynapac D25TDynapac

Dynapac D25TDynapac

Business5 years ago

Business5 years ago

Business3 years ago

Business3 years ago

Tech3 years ago

Tech3 years ago

Tech2 years ago

Tech2 years ago